Product and Service

High Efficiency Solar Products are Gradually Becoming Mainstream, Average Efficiency of JINERGY's Mass-produced Polycrystalline Solar Cells Breaks Through 18.7%

Recently, the No.1 photovoltaic module manufacturer of Shanxi - Jinneng Clean Energy Technology Ltd. (hereinafter referred to as “JINERGY”) - formally announced that average efficiency of its mass-produced polycrystalline cells has successfully broken through 18.7%. In addition, power of JINERGY's mass-produced polycrystalline module boosts enormously; the output rate of 270W modules has reached 60%, ranking in the industry-leading level. As of now, JINERGY has achieved the layout of three generations of industry-leading technologies – high efficiency polycrystalline, PERC and heterojunction.

Dr. YANG Liyou, General Manager of JINERGY, said, "The high efficiencysolar products have become the industry's direction and consensus. As the first batch of 'Top-Runners' with CQC certification, we are committed to construct the top 5% most technical and cost-competitive production base of cells & modules in the world through accurate technical innovation, optimized production process and efficient operation & management, and also vigorously promote the transformation and upgrading of photovoltaic manufacturing industry in China.

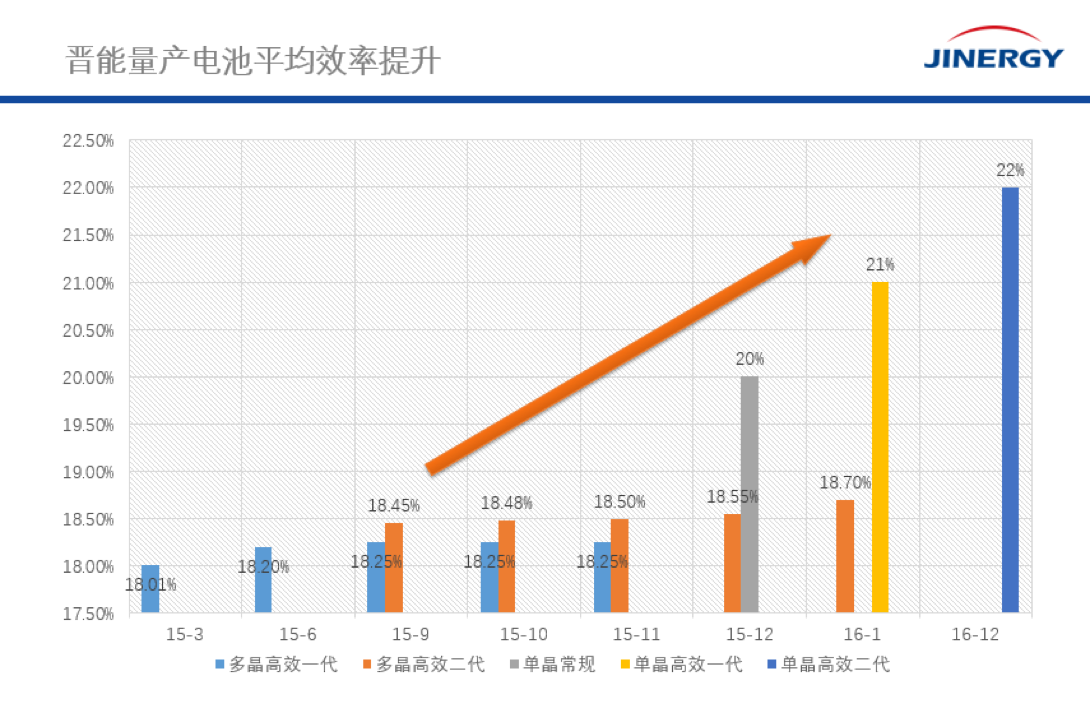

JINERGY's efficient mass-produced cells have been continuously achieving breakthroughs in recent months with average efficiency improved significantly; since March 2015 until January 2016, JINERGY has completed the upgrading & iteration of technology & process for efficient polycrystalline cells with the average efficiency of efficient polycrystalline cells ascending monthly from 18.01% at the early stage of production to 18.7%.

For back-passivated PERC cells, in January 2016, the pilot test efficiency of back-passivated mono-crystalline PERC cell developed by JINERGY has achieved 21.36%, higher than the average efficiency in this industry, which is 20.6-20.9%, reaching the leading level of the world.

Up to now, JINERGY has the annual production capacity of 600MW solar cells and 700MW solar modules in Wenshui, Shanxi province, and the production capacity of cells & modules in this production base is planned to be increased to 1.1GW respectively by the end of June 2016. Also, project of 2GW heterojunction efficient solar modules in Jinzhong, Shanxi, was launched at the end of 2015; it is planned to achieve the revolutionary production capacity of advanced solar cells & modules in the industry through three-year rolling research & development and construction, reducing the cost of photovoltaic power generation by 30% or above.

As the heterojunction efficient solar cells & modules project of JINERGY is put into operation, the Company will complete the layout of manufacturing technologies for three-generation's photovoltaic cells. In recent years, the Chinese government focused on accelerating the upgrading of photovoltaic industry and the promotion of core technologies, and launched the "Photovoltaic Top-Runner" program in early 2015. Since the implementation, there are 19 photovoltaic module manufacturers with the first Top-Runner certificate awarded by China Quality Certification Center, among of which, JINERGY is a company set up only for two years, which is the shortest; the high-efficiency core technologies have become a great magic for the Company to win.

Industry insiders believed that, as the further expansion of the leading base, the new energy bases in some areas of Ningxia, East Junggar Basin etc. require to use modules produced by the Top-Runners, so in 2016, the efficient modules will certainly occupy the domestic market with a larger proportion. By calculation based on the 20GW's annual installed capacity in 2016, the proportion of efficient modules in China will be in excess of 30%, accordingly, it is estimated that the demand for Top-Runner modules could be in excess of 6GW in 2016. In 2016, the efficiency and capacity of photovoltaic cells & modules are expected to rise simultaneously; therefore, how to win the corresponding market share of the Top-Runner modules by improving the core competitiveness will become the challenge that market players must face.

Faced with this severe challenge, JINERGY is fully implementing the intelligent manufacturing strategy featured by technological iteration, intelligent production, and flexible manufacturing. YANG Liyou believes that, during the "13th Five-year Plan" period, China's photovoltaic industry will make greater breakthroughs in terms of technology content of products and the intellectualization development of equipment. In the long run, Intelligent Manufacturing has become the only way for the transformation and upgrading of China's photovoltaic industry.

YANG Liyou said: "In the next five years, with an expectation of improving technical reserve and making rolling development in production, testing and research & development, the Company will select an appropriate opportunity to gradually increase capacity, expand product lines, realize automatic, intelligent and flexible photovoltaic manufacturing and take the lead in the high-end photovoltaic manufacturing service industry."

It is understood that, realizing the goal of "Commencement, Construction, Operation and Benefit Realized in the Year of 2014" , JINERGY has achieved the full capacity of product line over 2015 and was highly recognized both at home and abroad market, and has reached a close cooperation with top enterprises both at home and abroad such as Power Construction Corporation of China, China Energy Engineering Corporation Limited, China General Nuclear Power Corporation, Zonergy Company Limited, SunEdison from US and Toshiba from Japan, etc.